The transport principle of an air cushion system is similar to the movement of a hovercraft. Simply place the active parts (the air casters) underneath an object to lift the load and make it hover. There is no floor damage and because the friction is so low, you can move objects with only 1/1.000 of the force. The capacity per single air caster ranges from 100 to 40.000 kg’s.

The torus or bladder is made from polyurethane or neoprene rubber and both materials have their own advantages. Polyurethane’s biggest benefit is that it’s almost wear free, but the capacity is less than neoprene. Neoprene’s capacity is almost twice as big and the lift that can be generated is higher.

Polyurethane and neoprene air cushion transport systems

When you use the air cushion vehicle, it looks like you’re working with a hovercraft. Hover transport is exactly what we do and this can be achieved with an air cushion vehicle. The air cushion systems can be delivered with both kinds of materials: neoprene or polyurethane. Since we produce these air cushion systems ourselves, we can make them compatible with the products of other manufacturers such as Aerogo, Solving and Aerofilm Systems. The choice of using neoprene or polyurethane air cushions can be based on:

- Polyurethane material is more durable than neoprene material, but the polyurethane air cushion systems consume less air while using it.

- With a neoprene air cushion system, you can pick objects higher from the floor because the cushions have a higher lift. This might come in handy when you want to move a range of objects. Additionally, the neoprene air cushions have twice the capacity of polyurethane air cushions.

Replacement parts for the air cushions technology

Durable and high grade materials are the standard at Hover Transport Systems. We process the materials with our own precision machinery to create high quality products consistently. Furthermore, we invented a cost-effective production process which enables us to produce air cushion systems that are compatible with air cushion systems that are produced by other manufacturers. Our production process enables us to replace only the wearing parts. This can help you save up to 50% of costs in both purchasing and transport.

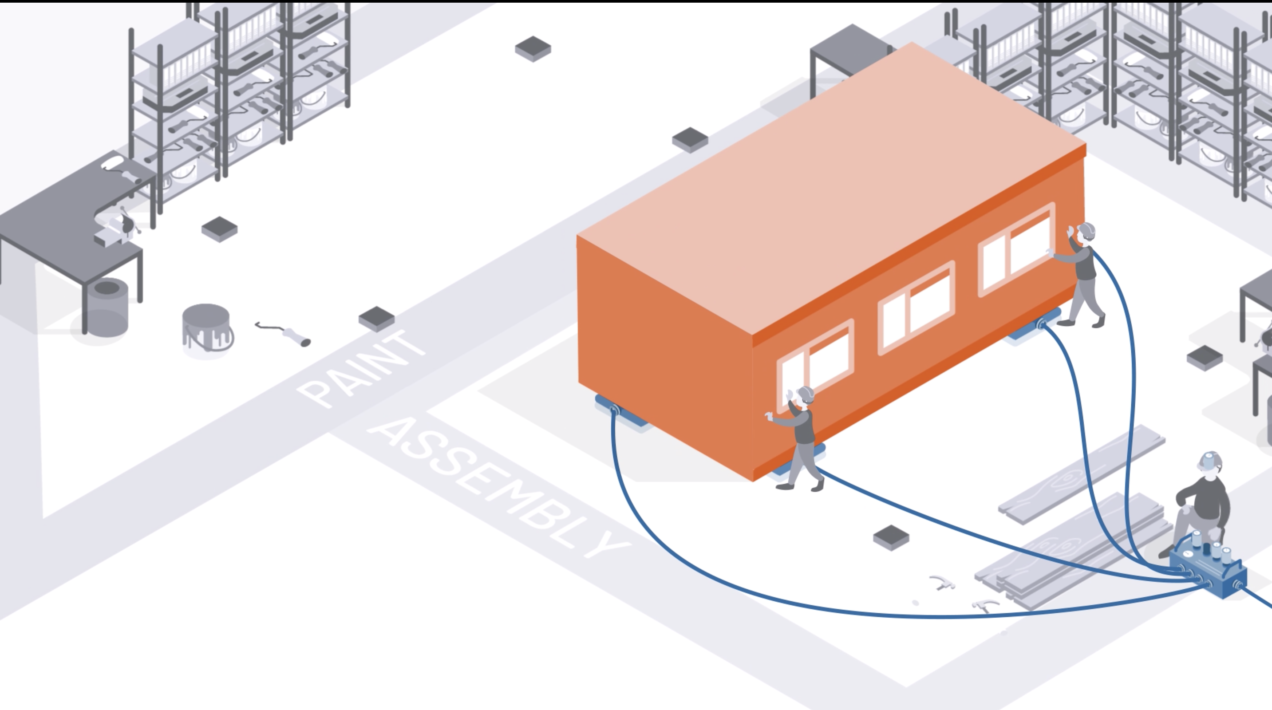

Air cushion transport systems in practice

Moving heavy loads is needed in different kinds of situations. Our air cushion transport system ensures that you can transport your equipment in a safe, fast and simple way.

- Safe: no harmful exhaust gasses are produced during transport and the loads are lifted from underneath

- Fast: the loads can be moved and positioned accurately after the installation of the air cushion system, which will only take a few minutes

- Simple: you’ll only need a suitable floor and compressed air